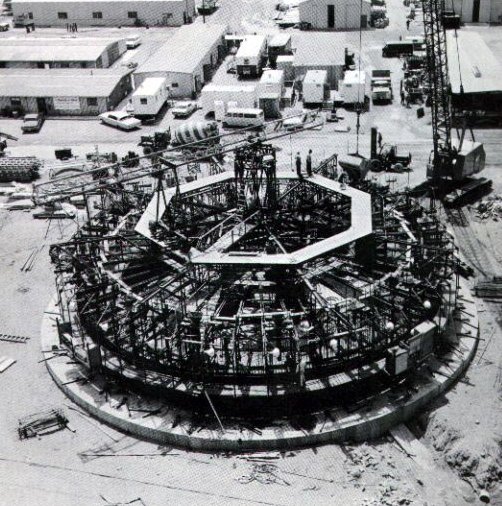

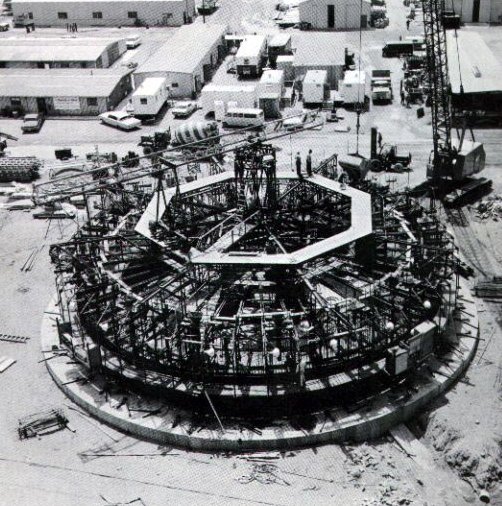

Slipform Chimney Construction!!

This "Slipform" assembly, pictured at the start

of construction, is an extremely

complicated form! A lot of controlled functions are especially designed to

adjust

this form's diameter, taper and the poured shell thickness, as this fancy

form

rides the jackrod supports embedded in the pre-placed concrete voids in the

shell

of the chimney! Below is a summary of some key construction

features:

1. The form rises non-stop (continuously) at a

rate of approx 1 foot/hour.

2. Each Jack is mounted to a yoke, to which is secured the inside and outside

form sheets and the working platforms.

3. Each Jackrod is removed upon completion of the shell. This leaves

typically 32 nominally 32" diameter holes internal to the

wall, extending

for the fill height of the concrete shaft (Most chimneys

built this way are

between 1000 and 1250 feet tall!). To protect from

water entrainment

after the chimney is completed, the jack rod voids are capped

top and

bottom with grout.

3. Radiused walers extend between the yoke frames on both the outside

and the inside surfaces of the concrete wall, and additional

form sheets

(which lap the sheets fixed to the yokes) will be attached to

these walers.

4. The diameter of the slipform assembly is controlled by a radial adjustment

fitted to each yoke frame, and the taper of the column

or slope of the wall

is set by an adjustment at the top of each yoke

frame.

See the cross-section!

5. The thickness of the concrete wall will be controlled by adjustments

that

are secured to the inside form sheets and the yoke

frames.

6. The construction of the shaft, that is the slipping of the form, is

usually

carried out continuously on a 24-hour day, 5-day week

basis, with a

temporary shutdown each weekend.

7. Cast-in inserts are not installed due to great difficulty experienced

in the

industry when a slipform is used. The practice is

to anchor all interior

and exterior securements (For balconies, fixtures, and

accessory items)

using Bulldog (or equal) self-drilling expansion

shields.

8. It is the usual practice of the slipform construction team to require

the

customer to provide centerline markings for starting

the chimney, such

as lines to demarcate the orientation of chimney

centerpoint, flue, access,

or other openings, as well as foundation slab elevation

data.

9. Hoisting the work personnel to the top platform of the slipform is

based on the

utilization of a "man-cage" rigged with cable

grabbers and two guide cables, so

that in the event of a hoist line cable breakage, the

grabbers would actuate and

suspend the cage from the guide cables. This man-cage

is typically operated by

a safety hoist, equipped with limit switches and

operated under power in both

directions. The customer supplies the hoist, if

there is no acceptance of this

lifting system.

I have no detail drawings or bill-of-materials

of the Custodis Construction

slipform system. These are proprietary (protected by patents), and were

owned and stored at a facility near the

Chicago office of Custodis Construction Co.

Div of Hamon-Cottrell.

Slipform Designers-Manufacturers:

Scanada Slipform

Some of the most talked about slipform and heavy-lift projects in the world

were accomplished by

the people now working for SCANADA. Every CANDU reactor in the world,

every coal preparation

plant in Alberta and British Columbia since 1981, as well as the hundreds of

grain elevators, stacks,

towers, bridge columns, and high-rise buildings constructed with SCANADA's

expertise are more

examples of why SCANADA has earned the respect of the construction industry

around the world.

In serving the world over the course of over 25 years (formerly known as Heede)

as designers, manufacturers,

developers and implementers of almost every imaginable application of slipform

and heavy-lift equipment

for almost every imaginable kind of construction project, the SCANADA group has

become a repository

of immense experience.

BYGGING-Uddeman

Gleitschnellbau GmbH (No Web itself):

Gleitschnellbau is a recognized leader in slipform construction

and the use of heavy lifting equipment.

This partnership has enabled Custodis to maintain efficiency and

cost-effectiveness throughout the

most challenging construction jobs and has stimulated the development of new

construction methods.

The shared slipform expertise has resulted in the development of hydraulic

jacking systems to safely

and efficiently lift chimney liners weighing 500,000 to 1,000,000 pounds or

more. In fact, most of the

tall chimneys (700 feet) in North America were built by the partnership of

Gleitschnellbau and

Hamon Custodis.

User Partnerships: Custodis

Ting Tai

Strabag

GBG

Gleitbau Salzburg

Balanced Engineering

and Construction

Structural Systems, Limited

Slipform Systems Austria

Back to the Resume

Home - Web Sections